Ninja is well known for its tender-crisp technology and has launched a series of equipment in this regard. Ninja Foodi is a pressure cooker that air fries too!

The device stating ‘SHUT LID’ has multiple reasons to display this error. Since Ninja Foodi has an active electronic control system that provides useful information to the end user.

To understand and mitigate the error code « SHUT LID » or <<TURN LID>> or <<OTHR LID>> during the operation of the Ninja Foodi. we strongly recommend going through the following details.

Ninja Foodi’s Inherent Features

Ninja Foodi has a special dual feature of pressure cooking and then air frying the pre-cooked meal up to a crispy, golden air-fryer finish.

These devices are designed with certain features that enhance the end user’s experience of the product.

Ninja Foodi has a built-in electronic control system that corresponds to the performance, operation & safety aspects of the device.

These controls are logged into a certain set of programs that the equipment is constrained to follow from the start to the end of the cooking cycle.

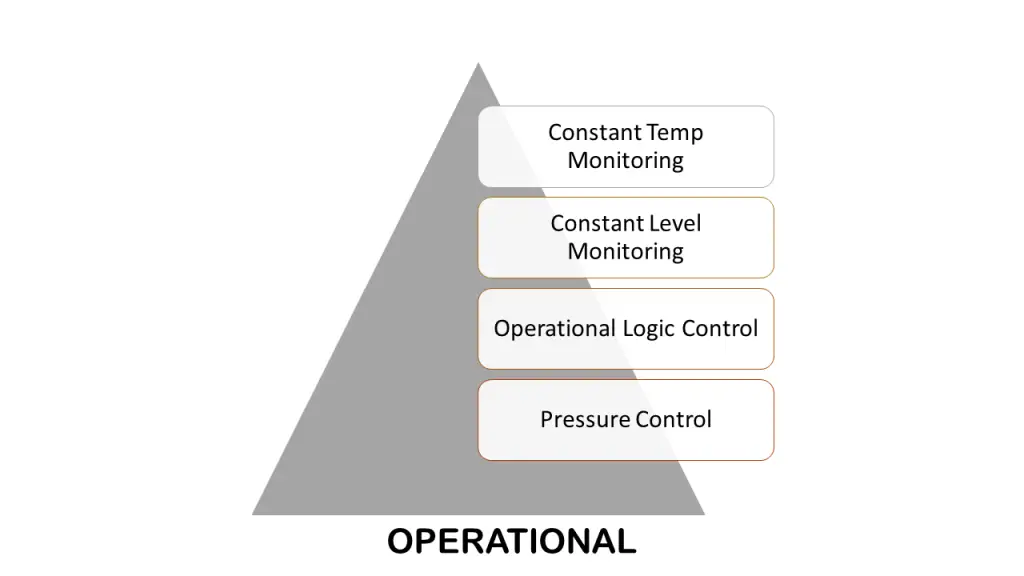

Operational Controls

The term ‘operational controls’ illustrates the parameters that are essential to ensure the operability of the Ninja Foodi.

These controls are again incorporated into the device controller.

The pre-defined parameters are checked and processed with necessary actions taken to ensure the smooth operation of the Ninja Foodi.

Constant Temperature monitoring

Temperature monitoring during, routine operation of the device is carried out via temperature sensors & transducers integrated into the Ninja foodi.

Failure of any component or malfunction can lead to a bizarre situation, with the device producing unwanted results!

Constant Level Monitoring

The level transducer in an air fryer is responsible for ensuring enough water level inside the device.

In a Ninja foodi, when the temperature of the water elevates it converts water into steam. The level transducers are only capable of measuring the liquid level (of water) till it converts into steam.

A faulty instrument can result in both; uncooked or overcooked food that the user may not have been desiring.

Operational logic control

The operational logic of the Foodi is patent and never disclosed by the manufacturers. However, it is of prime importance and helps you cook meals with ease & comfort at the touch of a button.

Ninja Foodi has the best operational logic control, which adds to the user experience of the product. This is why the majority of the users prefer to stick to Ninja’s products compared to other brands available in the market.

Pressure control

This function is really unique and keeps the pressure inside your ninja foodi regulated with the pressure release knob doing its job.

Overpressure protection and regulation are desired in that scenario if the knob fails to release extra pressure.

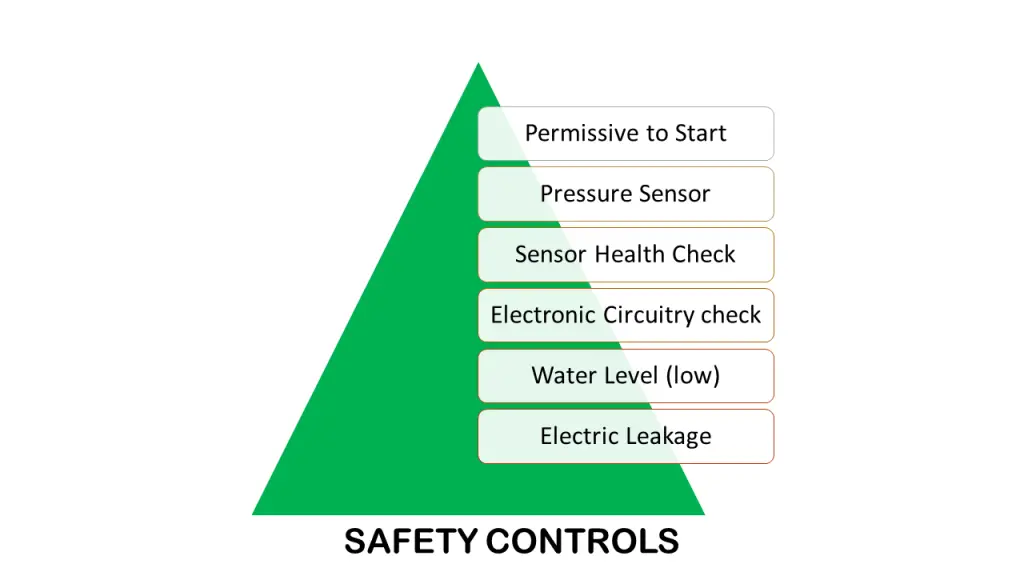

Safety Controls

Safety of the end user & the Ninja Foodi itself is of prime importance to the manufacturers since it directly affects the manufacturer’s reputation & sustainability in the masses!

Below important safety features are integrated into the equipment

Permissive to start

‘permissive to start’ refers to the key essential parameters & protections in place before the equipment is good to go for operation.

This primarily includes;

- Proper assembly of the device

- Availability of the AC voltage

- Availability of the transformer for DC voltage

- Heat/Temperature senors

- Overload protection etc.

Proper assembly of the device is a critical permissive to start that the device will need to ensure before it can allow safe operation.

The device will display the following errors if it detects an issue;

Error <<SHUT LID>> Error <<OTHR LID>> Error <<TURN LID>>

This error states that the equipment is facing a lid sealing issue. The top lid on a Ninja Foodi is supposed to hold the pressure inside the device.

If due to any reason the lid is unable to close, an error will pop up on the display stating the reason.

This is particularly due to the lid required for a particular function is not installed. For example, pressure cooking will require a matching lid. If you somehow install the air frying lid, it will display the relevant <<TURN LID>> error.

secondly, if the seal of the lid is damaged the controller will again pop up an error code for the replacement, as the pressure function will not commence.

Pressure sensor

Pressure in a Ninja foodi is scanned through a device that senses the pressure of the steam and tries to regulate it. However, it trips the device in case of overpressurization proactively to avoid the unforeseen.

Pressure regulation in a Ninja Foodi is done with the heating coil operation.

The sensor on an erratic behavior may cause undue shutting down of the device or a false alarm.

Sensor health check

Sensors inside the device are double-checked by the controller & ensure their availability as a safety feature.

The controller will not allow the Ninja Foodi to turn on in case of malfunctioning of any of the sensors inside the machine.

Electronic circuitry check

Healthy operation of the air fryer is only possible when the electronic circuity of the air fryer is constantly monitored and feedback is provided to the controller.

A malfunction or a wrong signal can lead to fires or damage to the equipment apart from the abnormal operation.

Low water level protection

Ninja Foodi has a low-level of water protection available that ensures the quantity of water is adequate enough to convert it into steam.

A half cup (1/2) or one full cups is normally recommended. However, it depends on the meal that you are cooking on the device.

Adequate water level shall be filled as per the supplier instruction book to avoid any alarm.

This steam release doesn’t allow pressure to build and the alarm appears.

This protection is the lifeline of the air fryer & a key safety feature.

Electric leakage protection

Since the device operates on an AC current, the chances of electric leakages from the device or the cables always persist.

ELCB provided in the device can shut down the equipment safely without compromising the equipment and the end user.

SHUT LID ERROR – Defined

Why is <<SHUT LID>> displayed & how to get rid of it?

This error code helps the end user to figure out effortlessly what went wrong and the steps required to get the Ninja Foodi back to normal.

SHUT LID error code states that the condition required for the Ninja foodi to safely operate have not been met. This is the result of either an improper lid installed for the corresponding action or the assembly itself has certain shortcomings. Installation, particles in the lid, or a damaged seal can result in triggering the SHUT LID problems.

This issue can be rectified by following the below steps;

-> Disassemble the Ninja Foodi

-> Check if the internals are clean

-> Remove any deposition on the sensors

-> Check & remove any deposition on the top lid seal

-> Check & remove any deposition on the sealing knob (at the top)

-> Go to settings & factory reset the device

-> Go to Menu and provide an adequate temperature range

-> Check permissive to start

-> Take an attempt to turn on the device

-> If the error code appears, factory reset the device

-> Follow the steps mentioned in the manufacturer guide

If the issue still persists, please visit your nearest after-sale services shop to rectify the WATR error display by thoroughly checking the internals.

Are there any other Error Codes apart from <SHUT LID>?

There are other errors as well that the Ninja Foodi displays to communicate the malfunction. This eventually helps the repair team and the end user to identify the exact root cause.

Conclusion

Ninja foodi can coupe up certain issues during operation or start-up since they are built with certain key features that enhance the user experience of the product in terms of performance, operation, and safety.

There are certain error codes that the device displays when they stop working. SHUT LID error code refers to either an improper lid installed for the corresponding action or the assembly itself has certain shortcomings. Installation, particles in the lid, or a damaged seal can result in triggering the error code.

Please get the device checked by following the steps mentioned in the above description.

We recommend following the OEM instructions in the handbook to resolve the issue or contact the Sales and Services center if the issue still persists.